Hydrogen Membranes

T3 hydrogen membrane products transform the performance of hydrogen membranes to meet the most demanding process requirements. Robust, even for the most hostile environments.

T3 is the only hydrogen membrane provider that supplies robust high flux membrane and contaminant resistant solution.

T3 hydrogen membrane products are designed for long life expectancy even with the most demanding operating environments. These membranes encompasses the licensed barrier technology and patented contaminant resistant technology by T3 to transform the performance of hydrogen membranes to meet the most demanding process requirements.

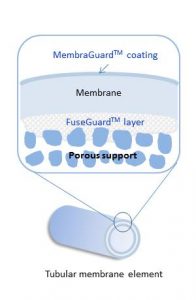

T3 hydrogen membranes use stainless steel support for superior industrial handling and product purity. FuseGuard™ provides the necessary barrier between the membrane layer and the porous stainless steel support to ensure the integrity and the performance of the membrane to purify hot gases throughout the product lifespan. This technology has been repeatedly tested in both laboratory and coal gasifier setting for thousands of hours and maintained its performance. It is the only barrier layer in the market today that has gone through such demanding testing.

MembraGuard™ Coating provides the revolutionary protection for applications where sulfur and other troublesome contaminants are present. The coating eliminates the contact of these trace gases to the surface of the membrane, allowing only hydrogen to pass, blocking all other gases. Its sulfur resistance power is at least 10x over the competitor with no added resistance to flow. MembraGuard™ coating provides a smart way to protect the membrane even in the most hostile environments.

Product Information

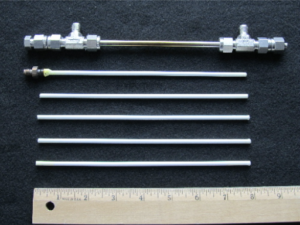

Supported Membrane

Hydrogen Membranes of palladium or palladium alloy can be ordered with or without MembraGuard™ coating. They are available in tubular form. Standard nominal diameters are 3/8″, 1/2″, 3/4″, and 1″. Standard lengths are 3′, 6′, 12′ and 18′. Modules of single membrane tube or multi-tube are designed according to customers’ specifications. Please inquire about non-standard sizes or forms and other product information.

Unsupported Membrane

Free standing palladium or palladium alloy defect-free sheet membranes from 10 micron in thickness are available in various sizes. Please inquire about sizes that fit your need.

Ceramic Membranes

Ceramic membranes can withstand high temperatures, extreme acidity or alkalinity and high operating pressures, making them suitable for many applications where polymeric and other inorganic membranes cannot. Ceramic membranes are increasingly being used in a broad range of industries such as biotechnology, pharmaceutical, food and beverage, petrochemical, microelectronics, and power generation. The main usages of ceramic membranes are for both gas separations and with nano- and micro-filtration.

Ceramic membranes are constructed from multiple ceramic layers and formed into an asymmetric element. These elements are grouped together in housings to form modules. Depending on the requirements of the application, different types of ceramic material are used. T3 has used materials such as α-alumina, γ-alumina, silica, and Perovskite to form support, intermediate layer and the outermost functional layer. Pore sizes ranged from completely dense, to sub-micron.

T3 has developed proven strategies to tailor pore structure and membrane surface functionality for specific application. The ability to control pore size and pore size distribution at various layers is the key to producing a defect free end product with high selectivity and high flux. The ability to control material surface properties is essential to meet customer’s unique requirements.

T3 has developed ceramic membranes for applications ranging from oxygen selective membrane reactor, carbon dioxide capture to high temperature hydrogen separation.